Best practices for using ros_control (hardware_interface) to send different data types to a PLC controller?

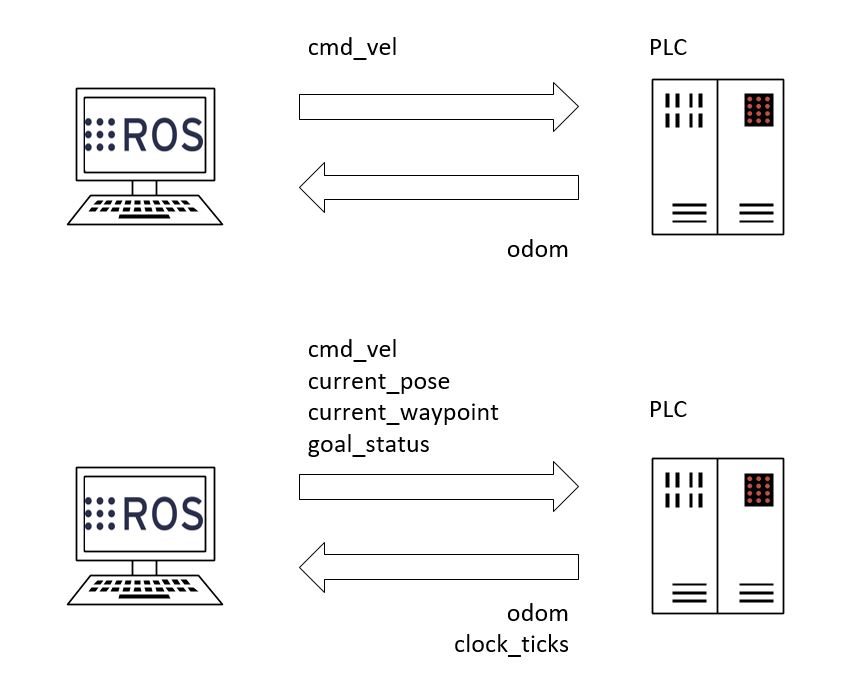

I'm using the ROS(Kinetic) navigation stack with an industrial AGV and a Siemens S7 PLC as the central controller. The motors and encoders are interfaced to the PLC. Currently the PLC communicates with ROS over TCP/IP sockets using ros_control and the diff_drive_controller plugin. This has worked well so far to receive odom feedback and send the corresponding wheel velocity commands.

Now I plan to send some extra information to the PLC, such as current waypoint, pose, goal status etc as part of the “telegram” (in the Write method). This additional data may not really make sense to be represented in the joint space so I’m unsure if a custom hardware interface such as the ones written for force-torque sensors, IMUs etc might make sense here. This information is internally published on various topics from different nodes and has to be inserted into the PC-PLC real time communication.

My understanding is that the controller plugin has to implement all the ROS related non realtime communication so that it is real time safe. The read and write methods implement the realtime specific communication to and from the hardware.

Could I introduce multiple subscribers in the diff_drive_controller plugin to gather this extra data from the ROS side? I notice that the cmd_vel callback in diff_drive_controller uses a Command object to “writeFromNonRT”.

Could I extend this struct to include other datatypes and perform a similar write function from multiple subscriber callbacks? If so, is there a way to ensure all of the callbacks are executed within the control loop “update” cycle? Or am I over complicating this?

How do I go about achieving this in a way that can be easily extended for newer data that I might want to send to the hardware (PLC)?